×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

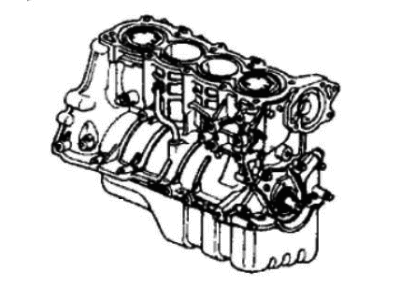

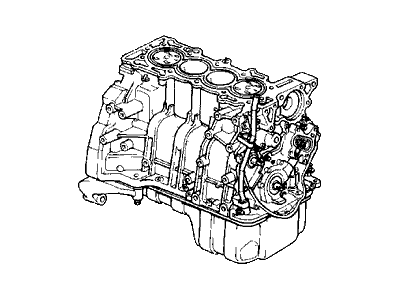

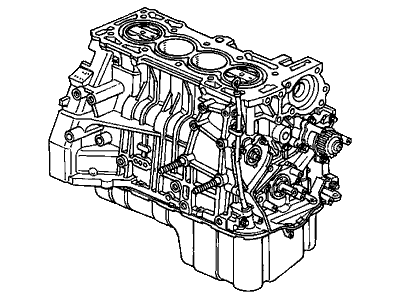

Genuine Honda Prelude Engine Block

Cylinder Block- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

67 Engine Blocks found

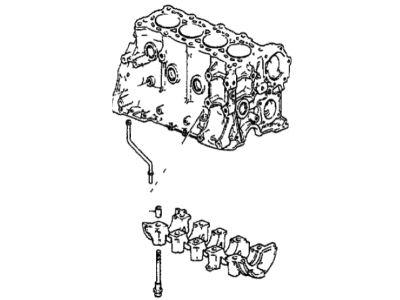

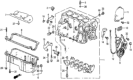

Honda Prelude Block Assy., Cylinder

Part Number: 11000-PT0-010$2067.23 MSRP: $2753.56You Save: $686.33 (25%)Honda Prelude Block Assy., Cylinder

Part Number: 11000-P13-000$2333.75 MSRP: $3108.55You Save: $774.80 (25%)Honda Prelude Engine Assy., Block (B20A5-015)

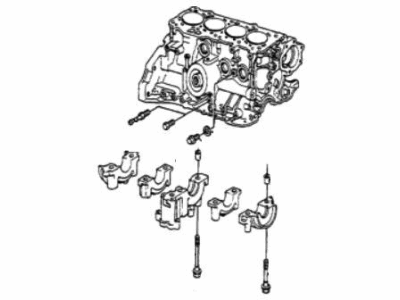

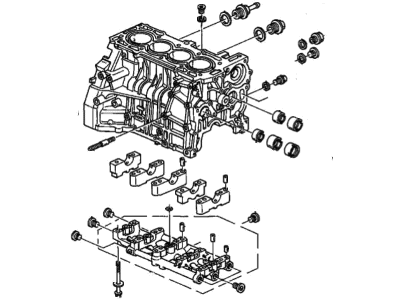

Part Number: 10002-PK2-661$3663.95 MSRP: $4880.38You Save: $1216.43 (25%)Honda Prelude General Assy., Cylinder Block

Part Number: 10002-P13-A00$4318.43 MSRP: $5752.16You Save: $1433.73 (25%)Honda Prelude General Assy., Cylinder Block

Part Number: 10002-P5M-A20$5001.22 MSRP: $6661.63You Save: $1660.41 (25%)Honda Prelude Block Assy., Cylinder

Part Number: 11000-PC6-010$2643.89 MSRP: $3521.66You Save: $877.77 (25%)Honda Prelude Block Assy., Cylinder

Part Number: 11000-PC1-000$2643.89 MSRP: $3521.66You Save: $877.77 (25%)Honda Prelude General Assy., Cylinder Block

Part Number: 10002-P14-A00$4318.43 MSRP: $5752.16You Save: $1433.73 (25%)Honda Prelude General Assy., Cylinder Block

Part Number: 10002-P5M-A24$5001.22 MSRP: $6661.63You Save: $1660.41 (25%)Honda Prelude General Assy., Cylinder Block

Part Number: 10002-P5M-A21$5001.22 MSRP: $6661.63You Save: $1660.41 (25%)Honda Prelude Block Assy., Cylinder (DOT)

Part Number: 11000-P5M-812$2031.85 MSRP: $2706.44You Save: $674.59 (25%)Honda Prelude BLOCK ASSY-, CYLN

Part Number: 11000-6ZD-810$1187.57 MSRP: $1581.85You Save: $394.28 (25%)

| Page 1 of 4 |Next >

1-20 of 67 Results

Honda Prelude Engine Block

In search of affordable OEM Honda Prelude Engine Block? Consider browsing through our extensive inventory of genuine Honda Prelude Engine Block. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

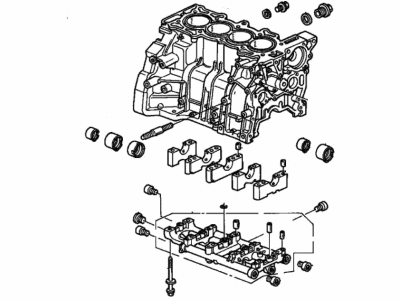

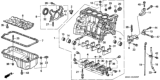

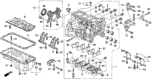

Honda Prelude Engine Block Parts Questions & Experts Answers

- Q: What does a thorough overhaul or rebuild of an engine block typically involve on Honda Prelude?A:In a total and complete overhaul or rebuild of an engine block, several parts of the block including the pistons, rings, bearings, timing belt or chain assembly and the Oil Pump are likely to be replaced, with overhead valve engines, the Camshaft and the lifters are also likely to be replaced. Cylinders should be bored and honed on the block oversize, or suitable new removable cylinder sleeves should be installed, provided the crankshaft is machined undersize to provide new wearing surface and necessary clearances. If only the piston rings are worn and all the other components are still new and as from the factory, the practice of replacing just the rings is very rare; normally, rings, bearings, and the oil pump should be replaced when in what is called a 'freshen up.' Cylinder ridges which are formed because the top piston ring is unable to reach the top of the cylinder should be machined off before new pistons are fitted. Engine disassembly should be done when engine is supported on a stand or on a bench so as to enable one work on the connecting rods and crankshaft. Timing chain or gear assemblies, the oil pick up and pump assemblies and any balance shafts should be removed and the crankshaft should be visible to mark the connecting rods and main bearing caps. The crankshaft is later withdrawn following the loosening of the main bearing caps. All components should be checked for wear or damages using tools as well as visual examination should be accompanied by test such as magnaflux or Zyglo for cracks. Main bearing alignment should be checked, and any damages may entitle the owner to align-boring. The surface of the deck should be free from any debris and it must be horizontally aligned in order that its thickness and width can be measured to its standard size. Cylinder bores should be checked for roundness and for tapering which is, measurements should be taken at different positions. The surface of the crankshaft should be checked for any signs of ovality and should be peaked and any minor scratch marks should be removed. For pistons, the possibility of crack and wear must be looked into; connecting rods on the other hand must be scrutinized to determine their straight nature. Any engine bearing shall be visually inspected; severely worn bearings have to be removed and taken to a machine shop. It is also recommended that the oil pump needs to be dismantled, washed and checked whether it is working efficiently or not. It is common for an engine block to be refinished by a machine shop and if new pistons are needed, they have to be assembled properly. In assembly, hygiene is sacrosanct and components ought to be washed before being embedded. Crankshaft and pistons are to be thoroughly fitted and placed so that they fit perfectly and no extra clearance is given. For mounted engines of OHV type, the camshaft, lifters and timing assembly should be fastened first, then the cylinder heads as well as other valve train parts. For OHC engines, cylinder heads should be bolted and timing assemblies fitted; and all engine covers and other components replaced as they were prior to removal following notes and drawings made at the time.

Related Honda Prelude Parts

Browse by Year

2026 Engine Block 2001 Engine Block 2000 Engine Block 1999 Engine Block 1998 Engine Block 1997 Engine Block 1996 Engine Block 1995 Engine Block 1994 Engine Block 1993 Engine Block 1992 Engine Block 1991 Engine Block 1990 Engine Block 1989 Engine Block 1988 Engine Block 1987 Engine Block 1986 Engine Block 1985 Engine Block 1984 Engine Block 1983 Engine Block 1982 Engine Block 1981 Engine Block 1980 Engine Block 1979 Engine Block