×

- Live Chat

- 1-888-984-2011

My Garage

My Account

Cart

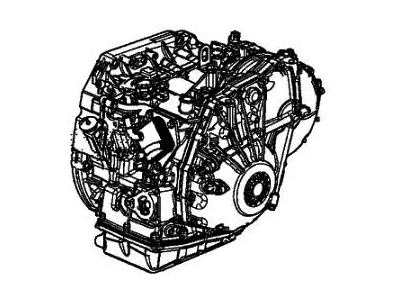

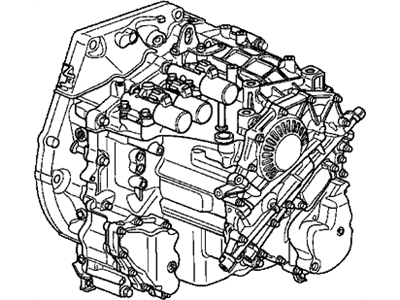

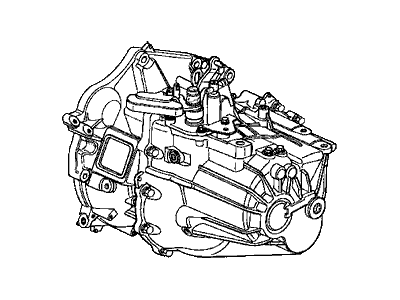

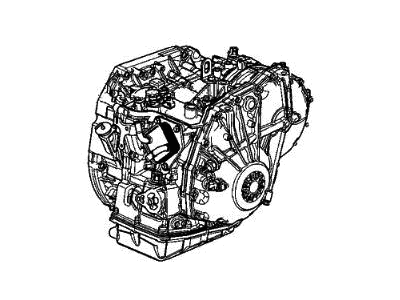

Genuine Honda Civic Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

173 Transmission Assemblies found

Honda Civic Transmission Assembly

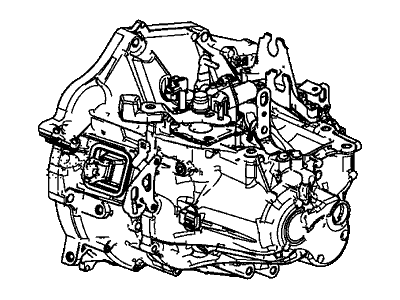

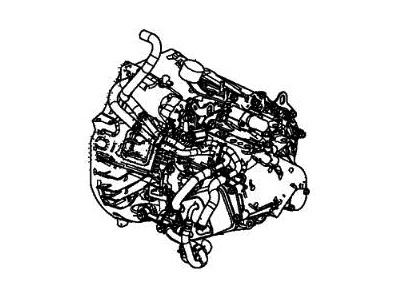

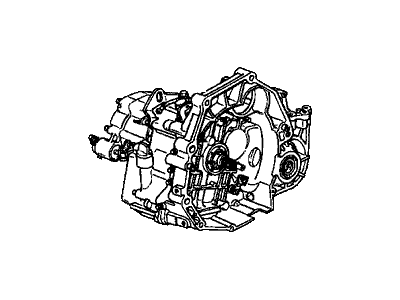

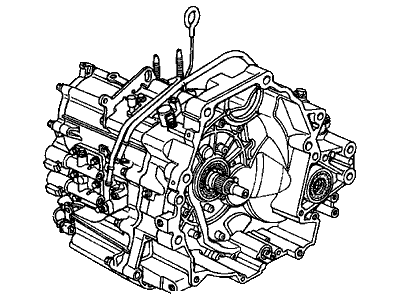

Part Number: 20011-RY1-P30$5092.01 MSRP: $6782.57You Save: $1690.56 (25%)Honda Civic BARE, TRNS ASSY

Part Number: 20011-5DE-R01$7410.43 MSRP: $9870.71You Save: $2460.28 (25%)Honda Civic Transmission Assembly (Automatic)

Part Number: 20021-P4R-A03$478.81 MSRP: $676.42You Save: $197.61 (30%)Honda Civic Transmission Assembly (Automatic)

Part Number: 20021-PLX-L03$1935.96 MSRP: $2734.95You Save: $798.99 (30%)Honda Civic Transmission Assembly (Mt)

Part Number: 20011-5CD-J50$5563.77 MSRP: $7410.95You Save: $1847.18 (25%)Honda Civic Transmission Assembly, Bare

Part Number: 20011-RPF-U43$4506.35 MSRP: $6002.46You Save: $1496.11 (25%)Honda Civic Bare, Transmission Assembly

Part Number: 20011-RPN-326$8767.09 MSRP: $11677.77You Save: $2910.68 (25%)Honda Civic Transmission Assembly

Part Number: 20011-PNR-325$3899.85 MSRP: $5627.48You Save: $1727.63 (31%)Honda Civic Bare, Transmission Assembly

Part Number: 20011-RPN-325$6753.45 MSRP: $9745.23You Save: $2991.78 (31%)Honda Civic Transmission Assembly (Mt)

Part Number: 20011-5CD-K50$3710.01 MSRP: $4941.74You Save: $1231.73 (25%)Honda Civic Bare, Transmission Assembly

Part Number: 20011-5CC-G50$4110.01 MSRP: $5474.54You Save: $1364.53 (25%)Honda Civic Bare, Transmission Assembly

Part Number: 20011-5GT-G50$4813.74 MSRP: $6411.91You Save: $1598.17 (25%)Honda Civic Transmission Assembly (Mt)

Part Number: 20011-P4A-H70$1623.21 MSRP: $3799.57You Save: $2176.36 (58%)Honda Civic Transmission Assembly (Automatic)

Part Number: 20021-PLX-L32$1228.78 MSRP: $1735.91You Save: $507.13 (30%)Honda Civic Transmission Assembly (Mt)

Part Number: 20011-PLW-P50$3465.09 MSRP: $4615.50You Save: $1150.41 (25%)Honda Civic Bare, Transmission Assembly

Part Number: 20011-5DE-R00$7410.43 MSRP: $9870.71You Save: $2460.28 (25%)Honda Civic Transmission Assembly (Mt)

Part Number: 20011-RPN-316$8767.09 MSRP: $11677.77You Save: $2910.68 (25%)Honda Civic Transmission Assembly

Part Number: 20011-PNR-345$3361.94 MSRP: $5627.48You Save: $2265.54 (41%)Honda Civic Transmission Assembly (Mt)

Part Number: 20011-PLW-X70$1359.61 MSRP: $5569.45You Save: $4209.84 (76%)Honda Civic Transmission Assembly (Automatic)

Part Number: 20021-P4R-A61$478.81 MSRP: $676.42You Save: $197.61 (30%)

| Page 1 of 9 |Next >

1-20 of 173 Results

Honda Civic Transmission Assembly

In search of affordable OEM Honda Civic Transmission Assembly? Consider browsing through our extensive inventory of genuine Honda Civic Transmission Assembly. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Civic Transmission Assembly Parts Questions & Experts Answers

- Q: How Can Problems With an Automatic Transmission Be Diagnosed on Honda Civic?A: In the event of a problem occurring, it will be necessary to establish whether the fault is electrical, mechanical or hydraulic in nature, before repair work can be contemplated. Diagnosis requires detailed knowledge of the transmission's operation and construction, as well as access to specialized test equipment, and so is deemed to be beyond the scope. It is therefore essential that problems with the automatic transmission are directed to a dealer service department or other qualified repair facility for assessment. Note that a faulty transmission should not be removed before the vehicle has been diagnosed by a knowledgeable technician equipped with the proper tools, as troubleshooting must be performed with the transmission installed in the vehicle.

- Q: How to remove and install a Transaxle on a Honda Civic?A: Read through the entire procedure before beginning. The engine and transaxle are removed as a unit from below, then separated outside the vehicle. Removal starts with setting the steering wheel straight ahead and locking it. Adjust the steering column tilt and telescoping to the center positions. Under the driver's side of the instrument panel, remove the steering column coupler cover. Use wire to tie the upper and lower ends of the column shaft together at the U-joints to prevent the lower part from sliding out after disconnecting from the rack and pinion. Loosen the pinch bolt at the lower U-joint. Open the hood, cover the fenders and cowl, then remove the air intake duct, air filter housing, and, on Civic models, the plastic fasteners, upper cover, wiper arms, wiper cowl, and lower cowl panel. Remove the battery, battery tray, and the PCM and bracket. On CR-V and Civic CVT models, disconnect the Shift Cable from the transaxle. Label and disconnect all vacuum lines, emissions hoses, electrical connectors, and harness clamps/brackets. Disconnect the transaxle fluid cooler lines and unbolt the ATF warmer from the transaxle on specific models. Support the engine with an engine support fixture or hoist. Remove the upper transaxle-to-engine bolts, ground cable, transaxle mount, and bracket. After raising the vehicle, remove the wheels, engine splash shield, inner fender splash shields, and drain the transaxle fluid. Remove the subframe. On certain models, unbolt the ATF warmer. Remove the torque converter cover, mark the relationship of the torque converter to the driveplate, and remove the bolts connecting them. Remove drive axles, intermediate shaft, catalytic converter, and pipe or transfer case on specific models. Support the transaxle with a jack, remove the remaining transaxle-to-engine bolts, and lower the transaxle from the vehicle. Installation starts with flushing the transaxle cooler and hoses. Ensure the torque converter hub is engaged in the transaxle pump and raise the transaxle into position. Align marks on the torque converter and driveplate, engage the dowel pins, and tighten the transaxle-to-engine bolts. Continue the installation by tightening the subframe bolts, driveplate bolts, driveaxle/hub nuts, and using new O-rings on the ATF warmer. Refill the transaxle with lubricant, start the engine, shift through gears, and check fluid levels. Finally, road test the vehicle for any fluid leaks.

Related Honda Civic Parts

Browse by Year

2021 Transmission Assembly 2020 Transmission Assembly 2019 Transmission Assembly 2018 Transmission Assembly 2017 Transmission Assembly 2016 Transmission Assembly 2015 Transmission Assembly 2014 Transmission Assembly 2013 Transmission Assembly 2012 Transmission Assembly 2011 Transmission Assembly 2010 Transmission Assembly 2009 Transmission Assembly 2008 Transmission Assembly 2007 Transmission Assembly 2006 Transmission Assembly 2005 Transmission Assembly 2004 Transmission Assembly 2003 Transmission Assembly 2002 Transmission Assembly 2001 Transmission Assembly 2000 Transmission Assembly 1999 Transmission Assembly 1998 Transmission Assembly 1997 Transmission Assembly 1996 Transmission Assembly 1995 Transmission Assembly 1994 Transmission Assembly 1993 Transmission Assembly 1992 Transmission Assembly 1991 Transmission Assembly 1990 Transmission Assembly 1989 Transmission Assembly 1988 Transmission Assembly 1987 Transmission Assembly 1986 Transmission Assembly 1985 Transmission Assembly 1984 Transmission Assembly 1983 Transmission Assembly 1982 Transmission Assembly 1981 Transmission Assembly 1980 Transmission Assembly 1979 Transmission Assembly 1978 Transmission Assembly 1976 Transmission Assembly