×

- Live Chat

- 1-888-984-2011

My Garage

My Account

Cart

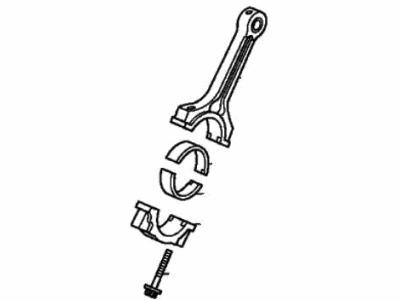

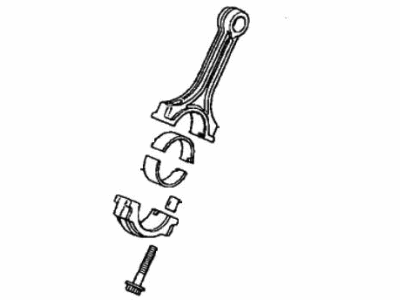

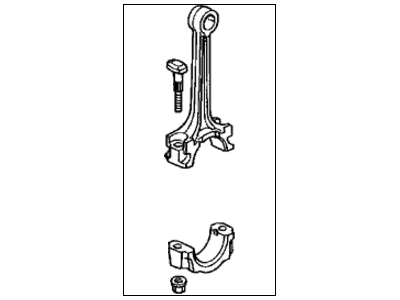

Genuine Honda Odyssey Connecting Rod

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Connecting Rods found

Honda Odyssey Connecting Rod

In search of affordable OEM Honda Odyssey Connecting Rod? Consider browsing through our extensive inventory of genuine Honda Odyssey Connecting Rod. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Odyssey Connecting Rod Parts Questions & Experts Answers

- Q: What steps must be taken before removing the piston and connecting rod assemblies on Honda Odyssey?A: Before the piston and connecting rod assembly can be pulled the cylinder heads and oil pan must first be stripped off. First, look for any ridges a the top limit of the ring travel within each cylinder-these are then pulled out with a ridge reamer to reduce the chances of piston failure. Once you have levelled the ridges, sit the engine on its side with the crank shaft facing up and measure the end-float of the connecting rod with feeler gauges and make sure that it is within the standard norms. Locate the positions of the connecting rods and the caps distinctly and then ease the bolts of the cap and undo them. Take off the connecting rod cap and the bearing insert gently and shove off the connecting rod and piston over the top of the engine. Perform this for all cylinders, and then tighten the caps and insert so that they do not get damaged. In case of piston rings, one must ensure that the gaps at the end meet the required standard; modification is done when necessary. The first to be fitted and compressed is the oil control ring after which are the middle and top rings according to their correct alignment. Before connecting the piston and its corresponding connecting rod, it should be ensured that cylinder walls are free from deposits and the crank-shaft has been fitted in position. The new bearing inserts are then fitted without lubricant and the piston ring gaps are oriented correctly before applying lubricant to the piston and rings; the assembly is then slid into the cylinder using a ring compressor. The other area to check on the connecting rod bearings is oil clearance using the Plastigagedatatype of the bearing inserts. Lubricant Plastigage deposits should be removed, bearing faces greased and pent rod cap bolted with new bolts to the required torque. That should be done with every assembly and cleanliness as well as correct orientation should be maintained. Last of all, turn the Crankshaft in the opposite direction to make sure no binding of the bearings and to check the end play of the connecting rod against a permissible limit.

Related Honda Odyssey Parts

Browse by Year

2022 Connecting Rod 2021 Connecting Rod 2020 Connecting Rod 2019 Connecting Rod 2018 Connecting Rod 2017 Connecting Rod 2016 Connecting Rod 2015 Connecting Rod 2014 Connecting Rod 2013 Connecting Rod 2012 Connecting Rod 2011 Connecting Rod 2010 Connecting Rod 2009 Connecting Rod 2008 Connecting Rod 2007 Connecting Rod 2006 Connecting Rod 2005 Connecting Rod 2004 Connecting Rod 2003 Connecting Rod 2002 Connecting Rod 2001 Connecting Rod 2000 Connecting Rod 1999 Connecting Rod 1998 Connecting Rod 1997 Connecting Rod 1996 Connecting Rod 1995 Connecting Rod