×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

Genuine Honda CRX Pistons

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

40 Pistons found

Honda CRX Piston (Over Size) (0.25)

Part Number: 13102-PM6-000$51.83 MSRP: $73.21You Save: $21.38 (30%)Honda CRX Piston (Over Size) (0.50)

Part Number: 13103-PM3-020$9.51 MSRP: $77.95You Save: $68.44 (88%)Honda CRX Piston (Over Size) (0.50)

Part Number: 13103-PM8-A00$41.35 MSRP: $58.40Limited AvailabilityYou Save: $17.05 (30%)Honda CRX Piston (Over Size) (0.25)

Part Number: 13102-PM3-000$47.29 MSRP: $66.81You Save: $19.52 (30%)Honda CRX Piston (Over Size) (0.25)

Part Number: 13102-PM3-010$47.29 MSRP: $66.81You Save: $19.52 (30%)

| Page 1 of 2 |Next >

1-20 of 40 Results

Honda CRX Pistons

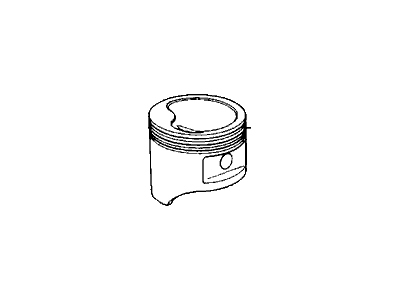

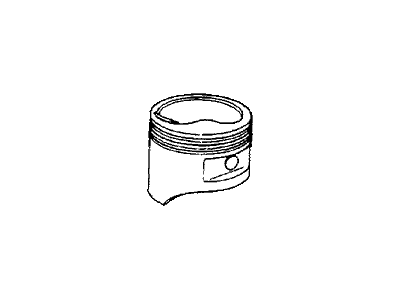

This Piston in Honda CRX vehicles helps to transform the combustion power to energy that is required to cause the motion of the car. This component is a major one of the internal combustion engine, its function is to transmit force created through the expansion of gaseous media to the crankshaft. Pistons for Honda CRX engines are commonly made out of cast aluminum alloys due to the want for as much lightweight as possible with a sufficient amount of strength, though high-performance engines often use forged or billet pistons. In the Honda CRX models over the years varying types of pistons have been used such as trunk pistons which provide support to lateral forces and uses oil ring for its lubrication. In this case, racing pistons are also made lightweight with the ultimate aim of increasing power when the engine is speeding. These pistons are very well designed, and their manufacturing is an important aspect in making Honda CRX a great car as it is, today.

In search of affordable OEM Honda CRX Pistons? Consider browsing through our extensive inventory of genuine Honda CRX Pistons. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

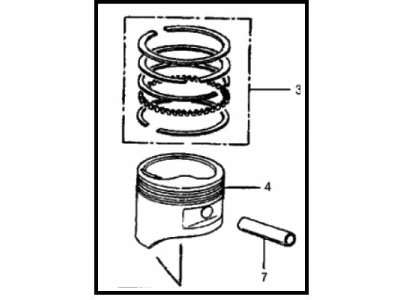

Honda CRX Pistons Parts Questions & Experts Answers

- Q: How do you remove and install the Connecting Rod and Pistons on Honda CRX?A:When draining coolant, be aware that ethylene glycol antifreeze can attract pets, posing a fatal risk if ingested, so always use a sealable container and reuse coolant unless contaminated or several years old. Minimize exposure to used engine oil, which can cause skin disorders, including cancer, by wearing protective gloves and washing hands promptly after contact. To begin removal with the engine out, disconnect the negative battery cable and remove the hood, then drain the Radiator and engine oil. Raise the vehicle and support it with safety stands, attaching a chain to the clutch cable bracket to relieve the center mount load without removing the left engine mount. Proceed to remove the center beam, engine lower mount, and Cylinder Head, then loosen and remove the Oil Pan and flywheel dust shield, tapping the corners lightly if necessary. Remove the oil passage block and Oil Pump assembly, then from underneath, take off the connecting rod bearing caps and push the pistons and connecting rods out, checking for carbon buildup or ridges before removal. When handling piston rings, avoid excessive force, and use a hydraulic press for piston pin removal. For installation, stagger the gaps of the three-piece oil ring and ensure markings on the second and top rings face upward, checking for smooth movement. Use a ring compressor to install the piston, applying oil to the rings and cylinder wall, and guide the connecting rod carefully during installation. Reassemble components in reverse order, ensuring proper alignment of bearing caps. For cleaning and inspection, remove rings with a piston ring expander, clean grooves carefully, and inspect for wear or damage, replacing pistons as necessary. Check the cylinder bore for wear using a telescope gauge and micrometer, measuring at specified points to determine clearance and whether oversized pistons are needed. When fitting new piston rings, compress them and measure the end gap, filing as necessary to avoid breakage, and inspect grooves for wear. Install rings in the correct order, ensuring proper positioning and spacing, and use a ring compressor for final assembly into the engine.