×

- Live Chat

- 1-888-984-2011

My Garage

My Account

Cart

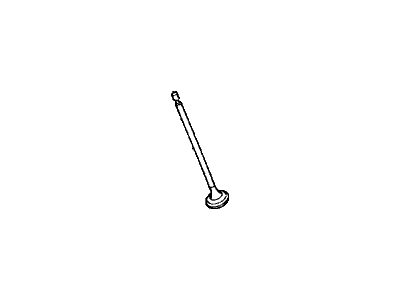

Genuine Honda CRX Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Exhaust Valves found

Honda CRX Exhaust Valve

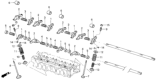

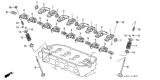

The Exhaust Valve in Honda CRX vehicles is among the most important components of the internal combustion engine since it opens to let out fumes of burnt fuel from the engine cylinders. This process is critical if one is to ensure the engine delivers optimum performance because, with a damaged Exhaust Valve, the power of the engine decreases, the engine may begin to misfire, the idling may become rough and fuel consumption increases. Exhaust Valves: Most likely, year models of Honda CRXs may have incorporated different types of Exhaust Valves but the changes in forms are not mentioned. The primary function has not changed with all these models and it is to expel gas with great efficiency for proper running of the engine. It was important that the Honda CRX owners learn about the function of the Exhaust Valve, to avoid any problems with the automobile engine.

In search of affordable OEM Honda CRX Exhaust Valve? Consider browsing through our extensive inventory of genuine Honda CRX Exhaust Valve. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda CRX Exhaust Valve Parts Questions & Experts Answers

- Q: How do you remove and install the Exhaust or Intake Valve on Honda CRX?A: To get rid of the Cylinder Head with some parts, it is required to detach the cylinder head from the engine, and the Camshaft from the cylinder head. Take the cylindrical shaped plastic mallet and using it strike the next part of the valve stem in order to release the keepers. Use valve spring compressor to compress the valve springs and unscrew the keepers, then unscrew the retainers and springs and valves from the other side of cylinder head while making sure that every part is in order to reuse it. For valve seal, you have to remove the seal from the valve guide, and if reusing the seals, then it is advisable to change the spring around the neck of the seal with exhaust valve seal having black spring and the intake valve seal having white spring. Check the valves for wear, damage or cracks and if so, reface them in that case, if new valve string have to be fitted then assure that the closely wound ends of new valve springs are towards the cylinder head. Replace the cylinder head with new valve seals, apply a thin layer of clean engine oil on the valve parts and then reverse the above procedure, give the cylinder head two to three taps after removing the spring compressor in order to set the keepers and valves correctly. One should be very careful when removing the valve spring compressor tool, as the springs might get shot off. Finish installing new gaskets to the part so that the job is thoroughly done. For examination, examine the check valve faces and seats for pits or burned spots and relegate to scrap any valve having a face which is in any way damaged. Valve faces should be at a 45-degree angle and refacing should be done by a professional machine shop. Check for any resultant scoring on the external surface of the valve stem, if none use solvent to wipe the part. Valve stem-to-guide clearance can be done with the help of a dial indicator if the tools are not available then take the components to a machine shop. Valve grinding operation must be done by a professional machine shop while valve lapping can be done by an inexperienced mechanic. For valve lapping turn the cylinder head upside down; apply a layer of oil on the valve stems and spread the grinding compound on the valve seats and fix the valves. Generally a valve lapping tool is used to lap until the valve seat has a polished finish to the seat with no sign of the grinding compound. The other way is applying suction cup to a drill rod for lapping; however, grooving the seat may occur at higher speeds.