×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

Genuine Honda Passport Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Cylinder Heads found

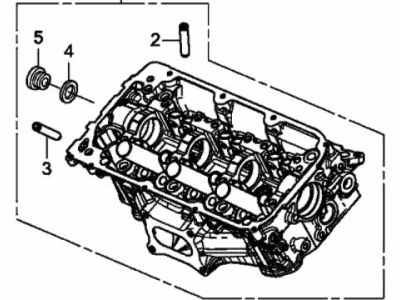

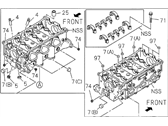

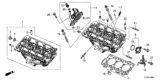

Honda Passport Cylinder Head Assembly, Front

Part Number: 12100-R9P-305$807.70 MSRP: $1056.28You Save: $248.58 (24%)Honda Passport General Assembly, Rear Cylinder Head

Part Number: 10005-5J6-H11$5160.39 MSRP: $6854.06You Save: $1693.67 (25%)Honda Passport General Assembly, Front Cylinder Head

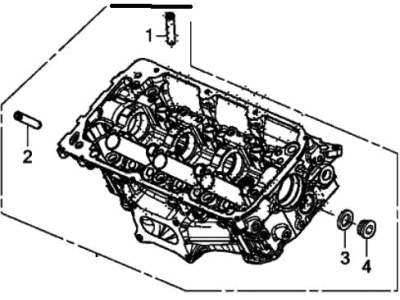

Part Number: 10004-5J6-A11$5207.73 MSRP: $6917.12You Save: $1709.39 (25%)Honda Passport Cylinder Head Assembly, Rear (Dot)

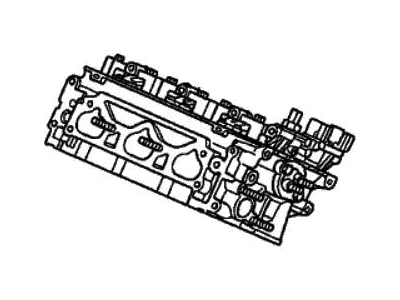

Part Number: 12300-R9P-810$866.20 MSRP: $1134.20You Save: $268.00 (24%)Honda Passport Cylinder Head Assembly

Part Number: 8-97104-323-0$765.77 MSRP: $1020.00You Save: $254.23 (25%)Honda Passport Cylinder Head Assembly

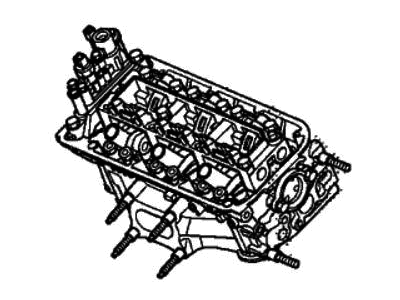

Part Number: 8-97089-717-1$221.23 MSRP: $1812.42You Save: $1591.19 (88%)Honda Passport Cylinder Head Assembly

Part Number: 8-97070-595-0$830.56 MSRP: $1106.31You Save: $275.75 (25%)Honda Passport Cylinder Head Assembly, Passenger Side

Part Number: 8-97329-288-0$1188.70 MSRP: $1583.36You Save: $394.66 (25%)

Honda Passport Cylinder Head

In search of affordable OEM Honda Passport Cylinder Head? Consider browsing through our extensive inventory of genuine Honda Passport Cylinder Head. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Passport Cylinder Head Parts Questions & Experts Answers

- Q: How can the cylinder head be removed and reinstalled on 2.3L and 2.6L four cylinder engine on Honda Passport?A:The cylinder head can be lifted with the intake and exhaust manifolds still in place or pulled off with them if the reason for this operation is, for example, gasket replacing. First of all, it is necessary to take out the intake and exhaust manifolds, to drain the cooling system, and to take off the upper hose of the radiator. Next, remove the thermostat housing, remove the heater hoses from the rear of the cylinder head and intake manifold and then remove the spark plug wires and position it aside and then take out the spark plugs. Remove the accelerator linkage, fuel line hose and all wires as well as vacuum hoses connected to the ECM and mark them for ease of reconnection. On early models with a carburetor, first, remove the fuel pump, next, use the jack to lift the car and put it on jackstands and the last step, remove the exhaust pipe at the exhaust manifold. That way free the valve cover and intake also take the No. 4 piston to TDC, remove the camshaft sprocket as well if following the right procedure. If the service engine light is associated with an Air Injection System, then remove the AIR hose and or check valve that is mounted on the exhaust manifold. Place a new head gasket on the cardboard and sketch the cylinders and bolt pattern on it, and show the front of the engine, and drill holes for the bolts. Tighten and relax the ten cylinder head bolts gradually in 1 / 4 turn clockwise anticlockwise using a star pattern from both ends about the center, and collect the bolts in the cardboard tray which will be used to hold the bolts for retightening. As you will find pulling the head up exhausting, you can easily wedge it on wooden blocks and give it a gentle hammer to free it off, then remove the cylinder head gasket and put the head on wooden block also. To install, the mating surface of Cylinder head and block should be free from deposit, using gasket scraper, clean these with lacquer thinner solvent or acetone. For head surface look for any nicks or scratches on the mating surfaces and use a file for minor ones, but for heavy ones machine the surfaces. To the threads in the head bolt holes, chase with a tap and clean the bolts on a vise. Place the gasket over the dowel pin, if the No. 4 piston is not at TDC, then proceed to do the following: Slowly lower the cylinder head until it is placed properly on the engine. The cylinder head mounting bolts should now be inserted and fitted on the cylinder head and the threads lubricated with engine oil on the threads and underside of the bolt heads and then tightened as per sequence and in accordance with the recommended torque. The last thing to do is to bolt the camshaft sprocket and close the engine in the reverse order to the foregoing steps. Lastly, add coolant, change the engine oil and filter, then crank the engine to check for any possibility of leakage, and check the coolant level at the operating temperature, adjust the idle and valve clearance to cold specifications.