×

- Live Chat

- 1-888-984-2011

My Garage

My Account

Cart

Genuine Honda CRX Alternator

Generator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Alternators found

Honda CRX Alternator Assembly (Denso)

Part Number: 31100-PE7-661$218.26 MSRP: $316.32You Save: $98.06 (31%)Honda CRX Alternator Assembly (Cha22) (Denso)

Part Number: 31100-PE1-663$173.94 MSRP: $246.90You Save: $72.96 (30%)Honda CRX Alternator Assembly (Reman) (Denso)

Part Number: 31100-PE7-661RMD$222.68 MSRP: $316.32You Save: $93.64 (30%)Honda CRX Alternator Assembly (Cha08) (Reman) (Denso)

Part Number: 31100-PE0-003RM$157.96 MSRP: $224.12You Save: $66.16 (30%)

Honda CRX Alternator

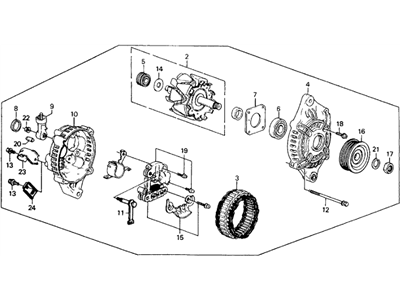

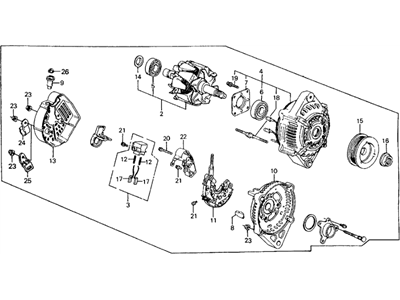

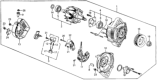

The alternator is one of the essential parts of the car, as well as it charges the battery and supplies power to the vehicle electrical system whilst traveling. It functions by converting mechanical energy in the form of engine output energy to electrical energy mostly in the AC format that requires to be rectified to DC format required to recharge battery and for powering parts. The usual make of the Honda CRX alternators is the two-piece cast aluminum housing, which contains a stator and rotor assembly. The rotor which is coupled with the help of a belt from the engine produces a magnetic field in which voltage is induced in the stator coils. From time to time will vary of alternator design: differences in excitation, for example, field coils or permanent magnets to the use of contemporary voltage regulation, and known that modern alternators may be included in the Transition Control Module (PCM). For those with higher electrical loads, high output alternators are provided for additional charging options to guarantee reliability of Honda CRXs.

In search of affordable OEM Honda CRX Alternator? Consider browsing through our extensive inventory of genuine Honda CRX Alternator. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda CRX Alternator Parts Questions & Experts Answers

- Q: How does the alternator convert mechanical energy into electrical energy and what are the key components and precautions involved in its operation on Honda CRX?A: The alternator generates electrical energy from mechanical energy provided by the drive belt by the process of electromagnetic induction. When the ignition switch is turned on current travels to the charging system light or ammeter from the battery through the wiring to the Voltage Regulator to the alternator. Turning the drive belt forces the rotor to rotate within the fixed stator hence generating alternating current, which when passed through the diode rectifier is converted to direct current which is usable. Most of this current recharges the battery and supplies the electrical system of the vehicle while a part of this, goes to the field windings of the alternator to increase its output. When the field windings reach a definite control voltage, the voltage regulator Short-circuits the circuit and retains the voltage stabilized. The alternator is located, close to no1 spark plug at the front side of the motor compartment and for models that have aac, is mounted on a rubber isolator on the driver side. Some of its safety measures include correct polarity connection when re-charging the battery, correct booster battery connections, NO 'quick charge', batteries' connection should be disconnected during charging, and cleanliness of all electrical contacts plus tightness on the alternator equipped automobiles. For belt tension adjustment, a force of 22 lbs. should provide a deflection of 0.35-0.43 in. for a used belt and 0.25-0.35 of the width of the body panel material used in the belt. for a new belt. The removal and installation include detachment of the negative cable, sometimes detachment of the air cleaner assembly, separation of electrical connectors, alteration of the alternator adjusting bolt, and detachment of the alternator belt and unit. Brush replacement involves using a rosin core soldering iron in order to avoid corrosion, counting the number of brushes required and on how it is to be done to ensure correct positioning of the new brushes. For Mitsubishi type alternators, some of the procedures involve pulling out the alternator, disconnecting the drive end housing and the rotor rear housing, checking brush length and putting the alternator back in place and then reinstalled.