×

- Live Chat

- 1-888-984-2011

My Garage

My Account

Cart

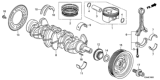

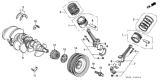

Genuine Honda Accord Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Crankshafts found

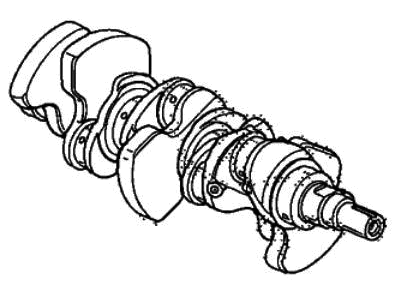

Honda Accord Crankshaft Complete

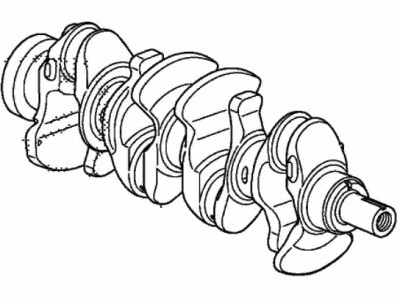

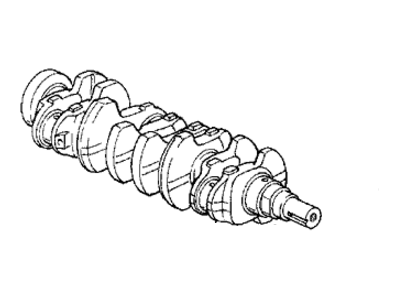

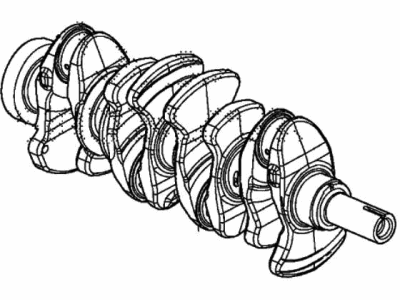

Part Number: 13310-6A0-A10$256.84 MSRP: $337.72You Save: $80.88 (24%)Honda Accord Crankshaft Complete

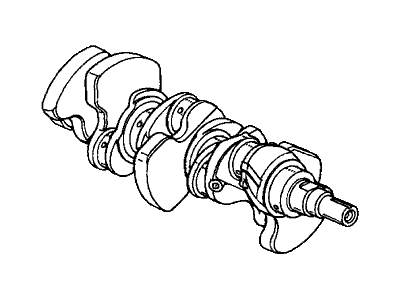

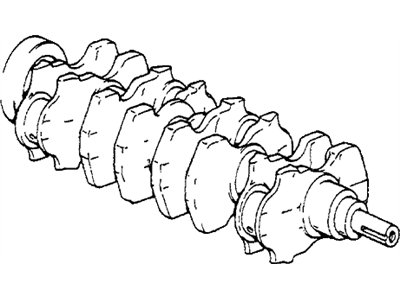

Part Number: 13310-5G0-A00$1033.59 MSRP: $1376.74You Save: $343.15 (25%)

| Page 1 of 2 |Next >

1-20 of 22 Results

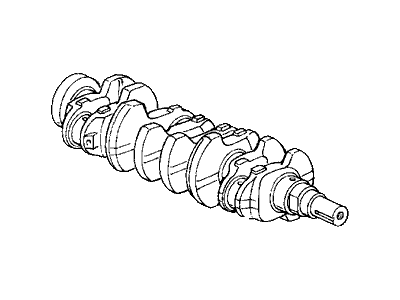

Honda Accord Crankshaft

In search of affordable OEM Honda Accord Crankshaft? Consider browsing through our extensive inventory of genuine Honda Accord Crankshaft. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Accord Crankshaft Parts Questions & Experts Answers

- Q: How can the crankshaft be removed and installed on Honda Accord?A: If again, we take off the flywheel, crankshaft pulley, timing belt or chain, oilpan, oil pump body, oil filter and piston/conrod assemblies then the crankshaft can only be removed when the whole engine has been piped out from the car. In V6 engines, the rear main oil seal retainer is to be removed from the block before the crankshaft can be removed. First, to check the crankshaft endfloat, fix a dial indicator on the flange of the crank and take its Zero reading. Turn the crankshaft to the right and set the indicator on 0, after that turn the crankshaft to the left and read the figures which should be around 0.003 to 0.010 inch. If a dial indicator is not available then clearance can also be measured with the use of feeler gauges. Turn and untighten the main bearing assembly bolts slowly until you can by hand remove the main bearing assembly or caps, but you have to be very careful not to drop the bearing inserts. Remove the crankshaft from the engine and it might be a bit hard due to its large size and probably weight. As for fastening, make certain the engine block and crankshaft are free from debris and were checked for their conditions. Place the engine block in an upside-down fashion, and if there are any inserts in the bearings, they should then be withdrawn, and the bearing areas should be cleaned. New upper main bearing inserts should be put in the engine block, and parallel to the oil holes; the thrust washer must be fitted properly. Clean the lower main bearing inserts and fit them into main bearing assembly's or caps, and should not tap to fit. Once you have gotten to clean the crankshaft, you need to place it in its proper place, to measure the main bearing oil clearance you need to use Plastigage. The lower crankcase or caps should be installed, but do not rotate them in order to not compress the Plastigage; however, tighten the bolts in the specified order. Delete the bolts and measure the Plastigage to ascertain the oil clearance; no dirt or oil must have affected the reading. If clearance is incorrect than measure the bearing insert sizes and observe the crank journal for any taper. Erase any Plastigage deposit on the journals and insert faces. For final positioning increase and remove it, then grease or apply assembly lube in the bearing areas and make certain that the crankshaft journals are clean before replacing the crankshaft. Lubricate the bearing insert faces and fit the lower main bearing bridge, using a torque wrench to restore all the bolts. Check the crankshaft end play once again and manipulate the crank shaft to and fro and make sure it glides freely, if not correct it. Last, fit in the new rear main oil seal into place.

Related Honda Accord Parts

Browse by Year

2022 Crankshaft 2021 Crankshaft 2020 Crankshaft 2019 Crankshaft 2018 Crankshaft 2017 Crankshaft 2016 Crankshaft 2015 Crankshaft 2014 Crankshaft 2013 Crankshaft 2012 Crankshaft 2011 Crankshaft 2010 Crankshaft 2009 Crankshaft 2008 Crankshaft 2007 Crankshaft 2006 Crankshaft 2005 Crankshaft 2004 Crankshaft 2003 Crankshaft 2002 Crankshaft 2001 Crankshaft 2000 Crankshaft 1999 Crankshaft 1998 Crankshaft 1997 Crankshaft 1996 Crankshaft 1995 Crankshaft 1994 Crankshaft 1993 Crankshaft 1992 Crankshaft 1991 Crankshaft 1990 Crankshaft 1989 Crankshaft 1988 Crankshaft 1987 Crankshaft 1986 Crankshaft 1985 Crankshaft 1984 Crankshaft 1983 Crankshaft 1982 Crankshaft 1981 Crankshaft 1980 Crankshaft 1979 Crankshaft 1978 Crankshaft 1977 Crankshaft 1976 Crankshaft