×

- Live Chat

- 1-888-984-2011

My Garage

My Account

Cart

Genuine Honda Ridgeline Trailing Arm

Trailing Control Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Trailing Arms found

Honda Ridgeline Arm, Right Rear Trailing

Part Number: 52371-SJC-A00$185.40 MSRP: $264.10You Save: $78.70 (30%)Honda Ridgeline Arm, Left Rear Trailing

Part Number: 52372-SJC-A00$185.40 MSRP: $264.10You Save: $78.70 (30%)

Honda Ridgeline Trailing Arm

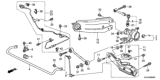

The Trailing Arm in Honda Ridgeline vehicles is a part and parcel of the trailing-link suspension system, which is an independent suspension system that locomotes the axle by means of the trailing arm and a lateral control arm. The primary role of suspension system is to reduce undesirable axle movements while increasing stability and control. The Honda Ridgeline adopts trailing-arm suspension system that has at least two links and may be provide with Panhard rod to manage the lateral movement of the wheels. In the course of using the Ridgeline, Honda has employed several styles of the Trailing Arm suspension including, the semi-trailing arm. This variation has a triangular arm that rotates in two axis, and this provides flexibility and independent movement of the rear wheels. Such designs lead to enhanced cargo capacity and a lower floor thereby making the Honda Ridgeline suitable for the driver who wants both utility and comfort.

In search of affordable OEM Honda Ridgeline Trailing Arm? Consider browsing through our extensive inventory of genuine Honda Ridgeline Trailing Arm. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Ridgeline Trailing Arm Parts Questions & Experts Answers

- Q: How to remove and install rear Trailing Arm and rear knuckle on a Honda Ridgeline?A: Loosen the rear wheel lug nuts. Raise the rear of the vehicle and support it securely on jack stands. Block the front wheels to prevent the vehicle from rolling. Remove the wheel. If you are removing the rear Steering Knuckle, loosen the drive-axle/hub nut. UPPER ARM Note: A special tool, available at most auto parts stores, is necessary to separate the upper arm ball joint from the rear Steering Knuckle. Support the lower arm B with a floor jack placed under the coil spring pocket. Remove the lock pin from the castle nut on the ball joint stud. Loosen the nut until there is a small gap between the Steering Knuckle and the nut. Install the ball joint separating tool, being careful not to tear the ball joint grease seal. Note: Apply grease to the portion of the tool that contacts the ball joint grease seal and to the threads of the bolt on the tool. Once the ball joint stud has been released from the Steering Knuckle, remove the castle nut and separate the arm from the Steering Knuckle completely. Remove the upper arm-to-sub frame mounting boll, then remove the arm. Installation is the reverse of removal, noting the following points:Tighten the ball joint stud castle nut to the lower torque figure, then, if necessary, tighten it a little more to line up the slots in the nut with the hole in the stud.Install a new lock pin.Raise the lower arm B with a floor jack to simulate normal ride height, then tighten the arm-to-sub frame bolt to the torque.Tighten the wheel lug nuts to the torque. LOWER ARM A Support the lower arm B with a floor jack placed under the coil spring pocket. Remove the lower arm-to-sub frame mounting bolt and the lower arm-to-Steering Knuckle mounting nut and washer. On 2007 Acura MDX models, remove the front trailing arm mounting bolls. Remove the arm from the vehicle. Installation is the reverse of the removal procedure. Be sure to install the washer on the arm-to-Steering Knuckle mounting stud with the concave side facing away from the arm. Before tightening the fasteners to the torque, raise the rear sus-pension with the floor jack to simulate normal ride height. Tighten the wheel lug nuts to the torque. LOWER ARM B Pilot and MDX models Support the lower arm B with a floor jack placed under the coil spring pocket. Remove the ABS wheel speed sensor harness from the lower arm. Remove the bolt securing the arm to the Steering Knuckle. Slowly lower the floor jack until the coil spring is extended, then remove the coil spring. Mark the relationship of the toe adjuster cam to the sub frame, then remove the pivot bolt and nut from the inner end of the arm. Remove the arm from the vehicle. Ridgeline models Support the lower arm B with a floor jack placed under the shock/coil spring assembly pocket and raise the suspension until it begins to compress. Remove the two nuts/bolts that secure the shock/coil spring assembly to the lower arm B. Remove the Steering Knuckle to lower arm B boll/nut and slowly lower the control arm. Mark the relationship of the toe adjuster cam to the sub frame then remove the pivot boll/nut from the inner end of the lower arm B. Remove the lower arm B from the vehicle. All models Installation is the reverse of removal, noting the following points:Align the mark you made on the toe adjuster cam with the mark on the sub frame.Raise the outer end of lower arm B with a floor jack to simulate normal ride height, then tighten the fasteners to the torque.Tighten the wheel lug nuts to the torque.Have the rear wheel alignment checked and, if necessary, adjusted. TRAILING ARM Remove the parking brake shoe assembly. Unbolt the brake hose and brake line brackets from the trailing arm. Unbolt the parking brake cable brackets. Support the lower arm B with a floor jack placed under the coil spring pocket. Remove the trailing arm-to-Steering Knuckle bolts, then remove the trailing arm-to-chassis mounting bolts. Remove the trailing arm. Installation is the reverse of removal, noting the following points:Tighten all fasteners to the proper torque specifications.It won't be necessary to bleed the brakes unless a hydraulic fitting was loosened.Have the rear wheel alignment checked and, if necessary, adjusted. REAR Steering Knuckle Remove the parking brake shoe assembly. On 4WD models, remove the drive axle/hub nut and discard it. On 2WD models, remove the axle shaft from the hub. On 2007 Acura MDX models, remove the hub and bearing assembly. Unbolt the brake hose bracket from the trailing arm and the brake line bracket from the Steering Knuckle. Remove the ABS wheel speed sensor and harness from the Steering Knuckle, then carefully place it aside. Note: There is no need to disconnect the electrical connector for the sensor. Support the lower arm B with a floor jack placed under the coil spring pocket. Detach the upper arm from the Steering Knuckle. Detach lower arm A from the Steering Knuckle. Detach the trailing arm from the Steering Knuckle. Detach the lower arm B from the Steering Knuckle. On 4WD models, carefully push the drive axle while removing the Steering Knuckle. Use a puller if the drive axle is stuck in the hub. CAUTION: Do not pull on the drive axle because the inner CV joint could separate. Installation is the reverse of removal, noting the following points:Tighten the ball joint stud castle nut to the lower torque figure, then, if necessary, tighten it a little more to line up the slots in the nut with the hole in the stud. Install a new lock pin.Install a new drive axle/hub nut.Raise the lower arm B with a floor jack, then lighten the fasteners to the torque.Tighten the wheel lug nuts to the torque.Tighten the drive axle/hub nut to the torque.