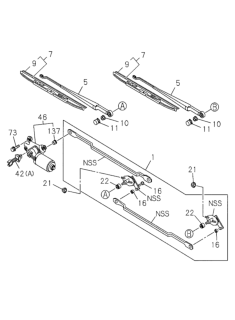

To discharge test the wiper motor circuit, the following should be performed Wire Colors and Location from the wiring diagrams. Power wires are generally thicker and painted in a more lively color than the ground wires which are thin and painted black. For voltage checks, use a grounded 12 V test light on each terminal on the connector. If the wipers are slow, first check the battery charge; if the charge is okay, then pull the wiper motor and manually working the wiper arms look for binding in the linkage or in the pivots, and then lubricate/repair while the motor is out of the way before reinstalling the motor. If the wipers still move slow down check for loose or corroded spots especially the ground and replace the motor if all are sound. If wipers do not operate, inspect the fuse; if the fuse is good, make a jumper wire directly to the motor's negative terminal, then try again. If the motor turns, dress the grounding connection, if not, check for voltage at the motor and should the absence of headlight voltage check the motor off of the truck with jumper wires. If the motor works outside the vehicle, the linkage should be inspected for binding; if it does not work, should be replaced. If there is no voltage on terminals of the motor, assistances must check for voltage on the switch side of the switch and check the wiring for continuity. In the case of blade wipers with only one working speed, one should check the wiring connections from the switch to the motor and where the wires are intact, replace the switch. If the interval function is not operating, inspect the wiring condition; if the wiring condition is good, replace the interval module. For wipers that do not park, use a voltmeter to probe the motor with the switch out; if voltage is detected, the limit switch is bad, which means that the motor will have to be changed. Check the voltages, if no voltage is present measure the limit switch wiring. If the wipers will not turn off unless the ignition is off, then remove the switch wiring; if it stops, then replace the switch but if the wipers continue to run, then the limit switch for the motor is bad and should be replaced. If wipers will not retract below the hoodline perform a mechanical check for obstructions and examine the wiring, if wiring is good replace the motor. For wiper motor replacement, use nut and bolt to remove the motor from the fire wall, its also necessary to unscrew the spindle nut as well as disconnection of electric connector. As for the rear wiper, there is the wiper arm retaining nut to be referenced, then loose it and remove the wiper arm. Next unscrew the drive spindle retaining nut, switch off the tailgate and unscrew the trim panel and access cover. Remove the linkage electrical connector, take off the bolts on the linkage bracket then retract the linkage and reach the wiper motor nuts. After all screws and the spindle nut have been removed, then installation is done in the reverse manner.

Posted by HondaPartsNow Specialist