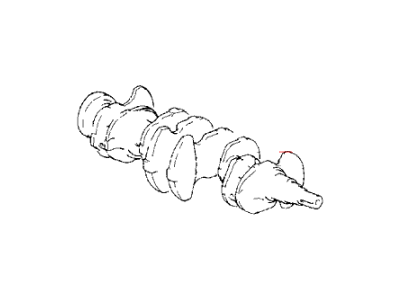

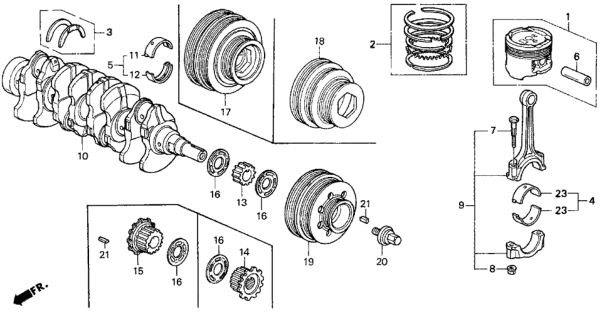

Honda engines are supported on crankshaft main bearings, and it is incorporated with a large bridge type main bearing assembly as a single unit. Most of the 1.6 L (1590 cc) engines feature a main bearing cap in conjunction with a separate bridge assembly, and both parts are removed in the same manner. First of all, the engine has to be taken out of the car and set on a working stand, then the bolts and washer securing the crankshaft pulley, front cover, and if there is such, the air conditioning idler pulley should be taken off. The deflection of the timing belt should be checked before the removal of the timing belt and sprockets. The engine should then be inverted on the work stand to take off the flywheel, rear seal cover, oil pan, gasket, oil pump inlet and oil pump assembly. All bearing caps should always be labeled in order to facilitate easy replacement in the correct positions. The crankshaft should be turned until the piston connected to the connecting rod form which the cap is being removed is at the top so that the connecting rod cap can be removed and subsequently the connecting rod with the piston. This should be done for the rest of joining pulser assembling before removing the majore bearing caps and then lifting the crank shaft out of the block with care in order not to damage the upper thrust bearings. For installation the bearings if are to be reused must be identified for correct location during the assembly of the equipment. Main bearing inserts should be taken out of the block and caps, new rear oil seal should be fitted in the rear seal cover. Plain Polyethylene Grease should be laid on the opposite side of the rear crankshaft-surface and no sealer should be given forward of the oil sealer fray-line. Every machined surface of the crankshaft should be scrutinised for sharp edges or digs, which are known to hasten bearing wear. If the crankshaft main bearing journals have been refinned to a certain undersize the same undersize bearings should be used, the parts should not be dirty or oily so as to cause deformation and failure of the bearings. The upper main bearing inserts should be placed in position with the tang fitted in the slot, while the lower main bearing inserts to be located into the bearing caps. It should then be slowly brought back to a position where the crankshaft can be slowly lowered into position; the clearance of each main bearing should be measured and bearings selected to give the required clearance. Upon the fitting of the bearings a light covering of heavy engine oil should be placed on the journals and bearings before replacing all bearing caps in their correct positions. The upper thrust bearing should be probed to ensure that it is parallel to the connecting rod bearing and the end play on the crankshaft should be measured and the upper thrust bearing should be replaced if the end play exceeds the specified measurements. If the end play is within limits, it is recommended to check faces of the thrust bearing for wearing or existences of dirt. New bearing inserts must likewise be provided in the connecting rods as well as the caps; while clearance must be checked and if there are regular clearances, heavy engine oil must be applied. A crankshaft throw should be rotated to the bottom of the stroke, so that the piston is pressed down to the extent that the rod bearings come in contact with the crankshaft journal and the next step will be to fit the connecting rod cap. When the piston and the connecting rod are assembled it is important to check the connecting rod crankshaft journal. The engine should then be turned on setting of the timing belt, sprockets, front cover, oil seal, crankshaft pulley. It is recommended that both the oil pan and the oil pump should be cleaned and that the oil pump should be primed prior to the installation of the oil pan, the oil pump and oil pump screen. In the case of the flywheel, it should be placed on the crankshaft and have the bolts fastened to the correct torque; the clutch disc and pressure plate should be fitted in case of manual transaxles. The engine should be placed in an upright position for the fitting of the oil level with the dipstick, fitting of accessory drive pulley and so as to adjust the drive as well as the accessory belts. Last, the clutch assembly or torque converter is to be fitted, accompanied by the oil pan and then the engine must be unbolted from the work stand for the purpose of it being fitted in the car. For cleaning and inspection of bearing oil clearance, the cap must be taken off the bearing to be checked and the crankshaft journal and the bearing insert must be cleaned properly. What happens is that Plastigage should be fitted along the loaded width of the bearing insert, and after replacing the cap and tightening it to the standard prescribed torque, the amounts of bearing clearance can be measured by comparing the width that is rendered on the scale of the Plastigage's envelope. If the bearing insert and journal look like they are in good condition, and within tolerances, it does not require service; otherwise, the cause of failure must be established before replacement. For crankshaft endplay and connecting rod side play, pry bar should be used to obtained the space existed between the thrust bearing and crankshaft and compare it with specifications. However it was seen that when excessive clearance is obtained, a main bearing with a thrust surface or crank machining might be required. Piston to connecting rod clearance can also be checked in the same way. If a journal is damaged, it can be machined back to a standard undersize, however it will be usual practice to replace a damaged crankshaft with reground shaft kit , as this comes with the relevant main and rod bearings and has been ground and polished to undersize and for superior reliability.

Posted by HondaPartsNow Specialist